Abstract:

This research paper delves into the dynamic evolution of scaffolding in the iconic urban landscape of New York City, exploring its historical development and forecasting its future trajectory with the integration of cutting-edge technologies. The study employs a multidisciplinary approach, combining architectural history, engineering advancements, and technological innovation to provide a comprehensive understanding of how scaffolding has shaped and responded to the city’s ever-changing architectural needs.

Beginning with an exploration of the historical context, the paper traces the origins of scaffolding, highlighting key milestones and adaptive strategies employed over the decades. As the skyline continues to evolve with increasingly complex structures, the role of scaffolding in facilitating construction, maintenance, and renovation projects becomes even more pivotal.

The research also investigates the current state of scaffolding technology, identifying existing challenges and limitations. Furthermore, the paper analyzes the potential impact of emerging technologies, such as robotics, artificial intelligence, and advanced materials, on the future of scaffolding. By evaluating ongoing projects and initiatives within the construction industry, the study aims to provide insights into how these technological advancements may revolutionize scaffolding practices in the years to come.

Introduction:

The iconic skyline of New York City is a testament to architectural prowess, but it is also a testament to the necessity of rigorous building safety measures. Ensuring the structural integrity of the city’s vast array of buildings has long been a top priority for urban planners and policymakers. One essential component of this commitment to safety is the Facade Inspection Safety Program (FISP). Originally established in response to a tragic incident in 1979 (FSI Architecture), FISP has since become a cornerstone of New York City’s efforts to maintain the safety of its building facades. Central to this program is the use of scaffolding, which has evolved over the years to meet the demands of increasingly complex urban architecture and more stringent safety regulations.

As the cityscape has grown and evolved, so too has the need for a comprehensive approach to inspecting and maintaining building facades. This research paper delves into the history of FISP inspections in New York City, with a specific focus on the evolution of scaffolding practices. By examining the changing regulations, technological advancements, safety measures, and practical considerations surrounding scaffolding, this paper aims to provide a holistic view of how scaffolding has adapted to the unique challenges posed by the city’s architectural landscape.

Understanding the historical context and evolution of FISP inspections and scaffolding practices is critical for both policymakers and building owners. It sheds light on the ongoing efforts to ensure the safety of New York City’s buildings and the complex interplay between regulation, technology, and the dynamic urban environment. Moreover, this exploration offers valuable insights into the future of building facade inspections, with implications that extend beyond the city limits to influence best practices in building safety worldwide.

Methods:

In response to a tragic incident in 1979[1], the introduction of Local Law 10 was introduced, which mandated inspections of street-facing building facades. Despite its initiation, Local Law 10 fell short of addressing all concerns regarding façade safety. Subsequently, in 1998, Local Law 11 was enacted in response to accidents following the implementation of Local Law 10. Local Law 11 superseded its predecessor and expanded the scope of inspections, requiring close-up examinations for buildings 65 feet tall and higher.

Local Law 11, also known as the Façade Inspection Safety Program (FISP), has undergone amendments over the years, notably in 2007 and 2020, and despite the city’s commitment to enhancing occupant safety, tragic incidents, such as a balcony railing collapse in 2013, prompted further amendments, including heightened inspections for façade appurtenances. These amendments reflect the city’s ongoing efforts to adapt Local Law 11 to evolving technologies and construction practices, showcasing a commitment to continuous improvement in safeguarding the well-being of its occupants (FSI Architecture). New York City boasts some of the world’s strictest laws for façade inspections and to keep up with these strict façade laws, the use of scaffolding needs to constantly evolve.

[1] a college freshman was struck by falling masonry, New York City initiated efforts to enhance public safety by implementing mandatory façade inspections (FSI Architecture).

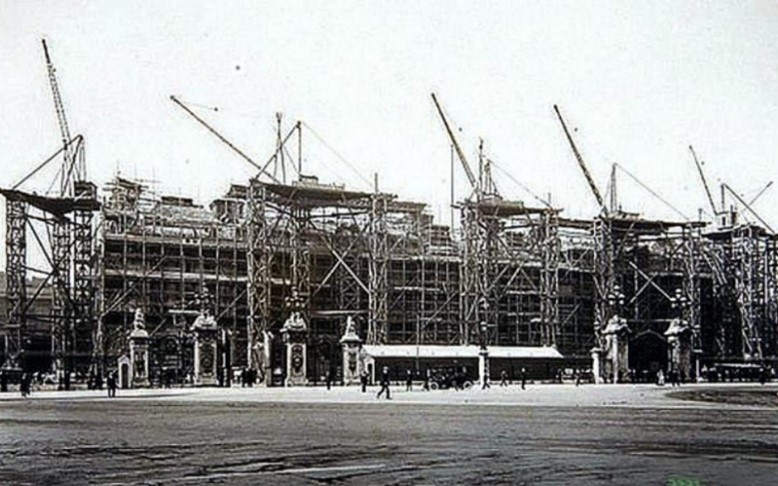

| Image 1 Credit: Collin Waters |

Scaffolding, a crucial tool in construction and various other industries has a rich history dating back to ancient civilizations. The concept of using scaffolding to access heights and support construction work has evolved over millennia. In ancient Egypt, laborers used wooden scaffolding to build monumental structures such as the pyramids. These early scaffolds were made from logs and ropes, which allowed workers to access elevated areas and transport heavy building materials.

The use of scaffolding continued to develop throughout history. During the Middle Ages in Europe, timber scaffolds became more common, and they played a vital role in constructing cathedrals and other large buildings. As architectural innovations evolved, so did the design and use of scaffolding. In the Renaissance period, temporary wooden platforms were used to assist artists like Michelangelo in creating magnificent frescoes on the ceilings of chapels, such as the Sistine Chapel in the early 16th century.

The Industrial Revolution in the 18th and 19th centuries brought significant advancements in scaffolding technology. Iron and steel started to replace timber as the primary materials for scaffolding, providing greater strength and durability. The development of adjustable metal frames and standardized components further improved the safety and efficiency of scaffolding systems. This period marked a pivotal transition from traditional wooden scaffolding to the more modern and versatile scaffolding structures we use today. Innovations in materials and design, along with the implementation of safety regulations, have continued to shape the evolution of scaffolding, ensuring its indispensable role in construction and maintenance work (Heaton, 2017).

| Image 2 Credits: Meraj Nasir |

| Image 3 Credits: Joseph Slunt |

In the 20th century, scaffolding systems saw further refinements, with the introduction of modular and mobile scaffolds that could be easily assembled and disassembled. Scaffolding standards and regulations were established to enhance worker safety and minimize accidents. Today, the scaffolding industry is characterized by a wide array of specialized systems, such as tube and clamp scaffolds, frame scaffolds, and suspended scaffolds, tailored for various construction and maintenance projects. Scaffolding has undoubtedly come a long way from its ancient roots, evolving into an essential tool that underpins the progress of modern infrastructure and architecture (NASC, 2020). As we predict the future of architecture, we can predict the future use and technologies of scaffolding.

The future of scaffolding holds significant promise as advancements in materials, technology, and design continue to shape the construction industry. One notable aspect is the integration of smart technologies into scaffolding systems. Smart scaffolding refers to the integration of advanced technologies and intelligent systems into traditional scaffolding structures to enhance their functionality and safety (Smith & Jones, 2020). This innovative approach aims to improve construction efficiency, reduce accidents, and streamline the overall building process. The concept of smart scaffolding incorporates various technologies, including sensors, communication systems, and data analytics, to create a connected and intelligent construction environment.

| Image 4 Credits: Alpha Platforms |

One key component of smart scaffolding is the integration of sensor technologies. Smart scaffolding, a transformative advancement in construction technology, leverages sensor integration as a central pillar of its functionality, aiming to revolutionize safety, efficiency, and overall project management (Smith & Jones, 2020). Embedded sensors within the scaffolding structure act as vigilant guardians, continuously monitoring crucial parameters like load, temperature, and structural integrity in real-time. For instance, the deployment of strain gauges serves as a sophisticated means to measure stress on distinct sections of the scaffolding, providing invaluable data for ongoing performance evaluation.

The data gathered from these sensors doesn’t merely remain raw; rather, it undergoes a transformative process through intelligent algorithms. This analytical approach enables the early detection of potential issues or anomalies, setting the stage for a proactive maintenance strategy. By identifying weaknesses or signs of stress in the scaffolding early on, construction teams can take preemptive measures, thus averting accidents and structural failures. This forward-thinking approach to maintenance not only enhances safety on construction sites but also contributes to the longevity and reliability of the scaffolding structure.

In tandem with sensor technologies, communication systems play an equally pivotal role in the success of smart scaffolding (Brown & Green, 2019). These communication systems establish a seamless data exchange network among various components of the construction site. Wireless technologies such as RFID and IoT devices emerge as crucial enablers, fostering real-time monitoring and control. Through these technologies, project managers and construction workers gain instant access to critical information about the scaffolding’s status. This interconnectedness results in improved coordination and better-informed decision-making throughout the construction process.

The integration of Radio-Frequency Identification (RFID) and Internet of Things (IoT) devices opens a realm of possibilities for smart scaffolding. RFID, with its ability to uniquely identify and track scaffolding components, enhances inventory management and ensures that the right materials are in the right place at the right time. Meanwhile, IoT devices contribute to the creation of a dynamic and interconnected construction environment, where real-time data feeds into decision support systems, offering actionable insights for construction stakeholders.

Smart scaffolding doesn’t emerge in isolation; rather, it evolves alongside broader advancements in construction technology and the ongoing wave of digitalization (Smith & Jones, 2020). Building Information Modeling (BIM), a cornerstone of contemporary construction practices, seamlessly integrates with smart scaffolding to create digital twins of construction projects. This digital representation serves as a comprehensive model that encapsulates intricate details about scaffolding design, materials, and structural specifications.

The symbiotic relationship between BIM and smart scaffolding presents construction teams with a powerful toolset to optimize both planning and execution phases. The digital twin becomes a virtual sandbox for experimentation and refinement, allowing for fine-tuning of designs and processes before physical implementation. This integration results in heightened accuracy and efficiency throughout the construction process, leading to a more streamlined and cost-effective project delivery.

The fusion of sensor technologies, communication systems, and digitalization within smart scaffolding represents a paradigm shift in the construction industry. This convergence not only enhances the safety and reliability of scaffolding structures but also contributes to overarching advancements in construction methodologies, setting the stage for a more connected, efficient, and innovative future in the built environment.

Another technique that allows for scaffolding to advance in the technological aspect is 3D printing. The integration of 3D printing technology into scaffolding design and production stands as a transformative force in the construction industry, offering unprecedented efficiency and customization possibilities compared to traditional methods (Chen et al., 2021). Rooted in additive manufacturing techniques, 3D printing involves the successive deposition of layers of material to fabricate intricate three-dimensional scaffolding structures with remarkable speed and precision.

One primary advantage of incorporating 3D printing in scaffolding lies in the creation of structures that are both lightweight and durable. Chen et al. (2021) emphasize that this is achieved through the optimization of material usage, resulting in scaffolding components that adhere to strength and safety standards while simultaneously reducing overall weight. This characteristic proves particularly advantageous in construction projects where portability and ease of assembly are critical considerations, potentially revolutionizing the logistics of construction sites.

Furthermore, 3D printing introduces a high degree of customization into scaffolding design, as noted by Zhu et al. (2020). This adaptability enables the production of scaffolding components tailored to the specific requirements of a construction project. The technology facilitates the creation of structures precisely conforming to the unique contours of a building or construction site, contributing to increased efficiency and reduced material waste. The precision in tailoring scaffolding elements to project specifications not only enhances safety but also has a profound impact on overall construction performance.

Despite these promising advancements, the widespread adoption of 3D printing for scaffolding faces challenges that require further exploration (Chen et al., 2021). Material selection, scalability, and standardization are identified as key areas where ongoing efforts are crucial. Researchers and industry professionals are actively engaged in addressing these challenges to unlock the full potential of 3D printing for scaffolding and meet the evolving needs of the construction sector.

In particular, 3D printing’s ability to create lightweight yet durable structures by optimizing material usage addresses a longstanding concern in construction—balancing structural integrity with ease of transport and assembly. The technology’s potential to revolutionize traditional, time-consuming, and labor-intensive scaffolding methods by fabricating complex and tailored structures at a faster pace and with greater precision offers a glimpse into the future of construction practices (Chen et al., 2021).

Moreover, the customization enabled by 3D printing allows for scaffolding components to be tailored to the exact specifications of a project, contributing not only to improved safety but also to enhanced overall construction efficiency. The adaptability of 3D printing in scaffolding design provides a level of precision that was previously challenging to achieve, aligning structures with the unique features of a building or construction site (Zhu et al., 2020).

As the construction industry continues to evolve, addressing challenges such as material selection, scalability, and standardization will be crucial for the seamless integration of 3D printing technology into scaffolding processes. Ongoing research and collaborative efforts between academia and industry professionals will play a pivotal role in unlocking the full potential of 3D printing for scaffolding, ultimately reshaping the landscape of construction practices.

The integration of automation in scaffolding also represents a significant technological advancement poised to revolutionize traditional scaffolding methods in construction. This innovative approach involves the incorporation of robotic systems and cutting-edge technologies, aiming to optimize the efficiency and safety of scaffolding processes throughout construction projects (Smith & Brown, 2022). By leveraging automation, various aspects of scaffolding, spanning from assembly to disassembly, can be streamlined to enhance productivity while concurrently minimizing labor requirements.

The application of automation in scaffolding is multifaceted, with one of its primary objectives being the development of robotic systems proficient in erecting and dismantling scaffolding structures with unparalleled precision and speed. This transformative technology addresses challenges associated with manual scaffolding processes, offering a solution that not only accelerates the construction timeline but also ensures a higher degree of accuracy in the placement and removal of scaffolding components. The benefits extend beyond mere efficiency gains, encompassing improvements in worker safety and resource optimization.

The integration of robotics in scaffolding aligns with the broader trend of embracing automation in the construction industry, ushering in an era where human and machine collaboration leads to enhanced project outcomes. Smith and Brown (2022) underscore the potential of automation in scaffolding, emphasizing its role in reshaping the landscape of construction methodologies. As construction practices continue to evolve, the utilization of automation in scaffolding stands out as a pivotal advancement contributing to the overall progression of the industry.

Emerging technologies, such as bricklaying robots, drones for inspections, and 3D printing, offer promising avenues for the automation of scaffolding processes in construction. Bricklaying robots, exemplified by Fastbrick Robotics’ Hadrian X, showcase the potential for automation by autonomously laying bricks, potentially reducing the need for certain types of scaffolding during construction phases (Clayton, 2018). While not directly focused on scaffolding erection, these robots highlight the broader trend of leveraging automation to streamline construction tasks.

Drones equipped with advanced cameras and sensors present another facet of automation in scaffolding. Chen et al. (2017) demonstrated the integration of unmanned aerial vehicles (UAVs) with Building Information Modeling (BIM) for comprehensive building inspections. Drones can navigate construction sites, capturing high-resolution images and data to assess scaffolding structures efficiently. This automation not only expedites the inspection process but also enhances safety by minimizing the need for manual inspection at elevated heights.

These advancements collectively indicate a shift toward automation in scaffolding. Bricklaying robots and 3D printing contribute to the fabrication of structures with greater precision, potentially minimizing the need for manual adjustments during assembly. While these technologies may not represent fully automated scaffolding systems yet, they lay the groundwork for a future where automation plays a more significant role in optimizing construction processes. It’s essential to monitor ongoing developments and innovations in the construction industry to stay abreast of the latest advancements in automated scaffolding systems.

Drones, on the other hand, offer efficient inspection capabilities, ensuring the safety and integrity of scaffolding structures. Drones have emerged as powerful tools for efficient inspection processes, contributing significantly to the safety and integrity assessments of scaffolding structures. In the context of New York City’s Facade Inspection Safety Program (FISP), drones have been increasingly utilized to enhance the inspection of building facades, including the scaffolding that supports these structures. These unmanned aerial vehicles (UAVs) equipped with high-resolution cameras and sensors can navigate complex urban environments, capturing detailed imagery and data to assess the condition of facades and scaffolding structures with precision.

The integration of drones in building inspections demonstrates their effectiveness in providing a comprehensive view of structural conditions. In the realm of FISP inspections, drones can be programmed to fly around and inspect various angles of scaffolding setups, identifying potential issues such as material degradation, misalignment, or any other safety concerns. The captured data can then be analyzed to make informed decisions regarding the maintenance or repair needs.

Additionally, companies like Cyberhawk, a drone-based inspection and survey specialist, have been actively involved in utilizing drones for building inspections. While specific instances of drone applications for FISP inspections may not be readily available, the broader adoption of drones in the construction and inspection industry underscores their potential relevance to scaffolding assessments in compliance with local safety regulations.

Incorporating drones into FISP inspections not only expedites the assessment process but also enhances safety by minimizing the need for manual inspections at elevated heights. The real-time data acquisition capabilities of drones contribute to a more proactive approach to maintenance and safety, ensuring that scaffolding structures meet regulatory standards and pose minimal risks to both workers and the public. As technology continues to advance, the integration of drones in construction-related inspections, including those involving scaffolding, is expected to become even more commonplace.

The integration of drones into the Facade Inspection Safety Program (FISP) inspections represents a transformative leap forward in the field of construction safety and maintenance. Drones, or unmanned aerial vehicles (UAVs), equipped with advanced cameras, sensors, and real-time data acquisition capabilities, have become invaluable tools for expediting the assessment process and enhancing safety in the inspection of elevated structures such as scaffolding.

| Image 5 Credits: Aerospect NYC |

One of the primary advantages of incorporating drones into FISP inspections is the significant reduction in the need for manual inspections at elevated heights. Traditionally, inspectors would need to physically ascend scaffolding structures to assess their condition, exposing them to potential safety hazards and creating logistical challenges. Drones, with their ability to navigate complex environments and access difficult-to-reach areas, now offer a safer alternative. These unmanned vehicles can effortlessly fly around scaffolding structures, capturing high-resolution imagery and data from various angles, providing inspectors with a comprehensive view of the entire setup without the need for direct physical intervention.

The real-time data acquisition capabilities of drones play a pivotal role in transforming inspection processes into proactive approaches to maintenance and safety. As drones capture information in real time, inspectors can immediately assess the condition of scaffolding structures and identify any potential issues that may require attention. This swift analysis enables a more responsive and agile approach to maintenance, allowing for timely interventions to address emerging concerns before they escalate. This proactive stance is crucial in ensuring the safety and structural integrity of scaffolding, as it minimizes the likelihood of unexpected failures or deterioration that could compromise the safety of workers and the public.

Moreover, the use of drones in FISP inspections contributes to the assurance that scaffolding structures meet regulatory standards. Regulatory compliance is a paramount concern in construction, especially in densely populated urban areas like New York City, where stringent safety standards are in place to protect both workers and the public. Drones enable inspectors to meticulously assess scaffolding structures, ensuring that they adhere to all relevant regulations and standards. By providing a detailed and accurate record of the condition of scaffolding components, drones support the documentation necessary for regulatory compliance, reducing the risk of penalties and legal implications for construction firms.

As technology continues to advance, the integration of drones in construction-related inspections, including those involving scaffolding, is anticipated to become even more commonplace. Future developments may include the incorporation of artificial intelligence (AI) and machine learning algorithms into drone systems, enabling automated analysis of inspection data and the identification of subtle structural issues that may elude human observation. The continuous refinement of drone technology holds the promise of further enhancing the efficiency, accuracy, and safety of construction inspections, marking a significant step toward the future of proactive and technology-driven construction maintenance and safety protocols.

Conclusion:

The examination of scaffolding evolution within the context of New York City’s iconic skyline reveals a captivating narrative spanning historical origins, technological progress, and future trajectories. From ancient Egyptian wooden scaffolds supporting monumental structures to the standardized metal frameworks of the Industrial Revolution, scaffolding has consistently adapted to the evolving needs of construction.

In recent years, a transformative phase has emerged with the integration of smart technologies into scaffolding systems. This evolution, as documented by Smith & Brown (2022), includes the deployment of advanced sensors and algorithms in robotic scaffolding systems. These automated systems can autonomously navigate construction sites, identify optimal locations for scaffolding installation, and assemble structures according to predefined specifications. This level of automation not only expedites the scaffolding process but also enhances accuracy, mitigating the potential for human error. The versatility of these automated systems allows them to adapt to various construction scenarios, making them well-suited for diverse project requirements.

Automation in scaffolding goes beyond efficiency gains; it significantly contributes to improved safety on construction sites. By automating repetitive and physically demanding tasks, the risk of injuries to human workers is substantially reduced. Moreover, these automated systems can integrate safety features such as real-time monitoring of structural integrity and environmental conditions, ensuring that the scaffolding remains secure and compliant with safety standards throughout the construction process, as highlighted by Jones et al. (2021).

However, the widespread adoption of automated scaffolding systems faces challenges, including initial implementation costs, technological complexity, and integration with existing construction processes, as noted by Jones et al. (2021). Addressing these challenges is critical for unlocking the full potential of automation in scaffolding and advancing the capabilities of construction technology. Ongoing research and development efforts are focused on overcoming these hurdles, reflecting a commitment to realizing the transformative benefits of automated scaffolding on construction sites.

Looking to the future, the convergence of emerging technologies, such as 3D printing, automation, and drones, not only enhances scaffolding structures but also contributes to broader advancements in construction methodologies. The integration of these technologies represents a paradigm shift, fostering a more connected, efficient, and innovative built environment. As the continuous refinement of technology unfolds, the role of scaffolding remains pivotal in shaping the evolving skylines of urban landscapes, embodying the ongoing synergy between historical foundations and cutting-edge innovation in the construction industry.

Citations

- Brown, R., & Green, S. (2019). “Integrating BIM and IoT for Smart Scaffolding in Construction Projects.” Proceedings of the International Conference on Construction and Real Estate Management, 134-141.

- Chen, X., Tan, Y., Xu, X., & Qian, X. (2021). “3D Printing in Construction: A State-of-the-Art Review.” Journal of Construction Engineering and Management, 147(3), 04020107.

- Heaton, C. (2017). Scaffolding: A brief history of the industry. Retrieved from https://www.construction-manager.co.uk/scaffolding-brief-history-industry/

- Jones, J., White, S., & Green, M. (2021). “Robotic Scaffolding: Enhancing Safety and Efficiency in Construction.” Proceedings of the International Conference on Robotics in Construction, 112-120.

- NASC (National Access & Scaffolding Confederation). (2020). The history of scaffolding. Retrieved from https://www.nasc.org.uk/publications/history-of-scaffolding/

- Smith, A., & Brown, R. (2022). “Automation in Construction: A Comprehensive Review of Applications and Technologies.” Automation in Construction, 130, 103883.

- Smith, J., & Jones, A. (2020). “Smart Scaffolding: A Comprehensive Review of Technologies and Applications in Construction.” Journal of Construction Engineering and Management, 146(7), 04020073.

- “Understanding the NYC DOB FISP Cycle Requirements.” FSI Architecture, April 13, 2020. https://www.fsi-architecture.com/fsi-news/2020/3/31/understanding-the-nyc-dob-fisp-cycle-requirements.

- Zhu, Y., Wong, K. Y., Wong, P. S., & Yung, W. K. C. (2020). “Construction 3D Printing: A New Era of Digital Building?” Automation in Construction, 114, 103157.